Export pallets

As an international business, shipping products across the world is essential for success. Therefore, selecting the right export pallet is a critical decision that should not be taken lightly. Q-Pall's export pallets are plastic pallets designed to ensure the safety and security of goods during transportation. This article will explain the different types of export pallets available, their benefits, and which type is best for your business’s needs. If you're shipping your products overseas, make sure to read this article.

+31 (0)413 353 111

Dimensions: 800 x 600 mm

Height: 145 mm

Weight: 2,0 kg

Racking load: 0 kg

Dimensions: 1200 x 800 mm

Height: 150 mm

Weight: 5,0 kg

Racking load: 0 kg

Dimensions: 1200 x 800 mm

Height: 150 mm

Weight: 7,0 kg

Racking load: 0 kg

Dimensions: 1200 x 800 mm

Height: 150 mm

Weight: 6,0 kg

Racking load: 0 kg

Dimensions: 1200 x 800 mm

Height: 150 mm

Weight: 7,0 kg

Racking load: 0 kg

Dimensions: 1200 x 800 mm

Height:149 mm

Weight: 5,39 kg

Racking load: - kg

Dimensions: 1200 x 800 mm

Height: 160 mm

Weight: 7,2 kg

Racking load: - kg

Dimensions: 1200 x 800 mm

Height: 160 mm

Weight: 7 kg

Racking load: - kg

Commonly used export pallet dimensions

Export pallets are an integral part of the international freight industry. Most manufacturers, suppliers and retailers rely heavily on them for their cargo transportation. To ensure that shipments are properly secured and safe to transport, it is important to understand commonly used export pallet dimensions.

The two most frequently used sizes for export pallets are 800 x 1200 mm and 1100 x 1100 mm. The 800 x 1200 mm size is slightly larger than a standard Europallet, but still small enough to fit into shipping containers or trucks easily. The 1100 x 1100 mm size is perfect for larger loads because it offers more support and stability during transit as well as easier handling in warehouses. Both sizes offer a maximum load capacity making them ideal for most general freight applications.

What are the advantages of export pallets?

Export pallets are an essential tool for businesses looking to transport products and materials from one destination to another. These lightweight plastic export pallets provide a safe and secure way of packing goods while allowing for easy loading and unloading. But what are the advantages of using export pallets?

Export pallets offer several benefits that make them ideal for both industrial and commercial applications. Their lightweight nature makes them easier to handle, stack, and store than traditional wooden or metal pallets. They also allow goods to be packed more efficiently, saving time in the process. Additionally, their durability ensures they can withstand multiple uses without breaking down or becoming damaged. Moreover, plastic pallets are not subject to the same international regulations as wooden ones, such as inspection requirements by ISPM15 certification standards. This reduces costs associated with compliance fees when shipping products overseas.

Export pallets made from plastics are an essential component of any international shipment. Not only do they ensure the safe transport of goods, but they also provide a number of advantages to businesses selling their products abroad.

Using export pallets also allows businesses to optimize product packaging and loading onto containers or aircraft for efficient transportation. They come in various sizes and shapes to suit different types of goods, so businesses can choose the best option for their products.

Export pallets are available in many versions

Pallets are an essential component in the shipping and transportation of goods. They come in many different versions, from light to heavy duty, to cater to a variety of needs. Many companies choose their pallets based on their specific requirements for load and weight capacity. Light export pallets are appropriate for smaller loads and lighter items, while medium-duty pallets suit heavier items such as boxes or crates. Heavy-duty pallets can handle even larger loads, such as manufacturing equipment or large containers.

Q-Pall offers a huge range of high-quality export pallets that meet your exact needs whether you’re looking for something light, medium or heavy-duty. With features like anti-slip surfaces and robust construction, these pallets will ensure your goods arrive at their destination safe and sound – every single time!

Still have questions left about export pallets?

Do you still have questions left about export pallets? We understand that finding the right export pallet for your international needs can be tricky. That’s why it’s important to rely on an expert who can provide the best advice and answer any of your lingering questions.

If you need help finding the perfect export pallet, our team of experts is here to assist you every step of the way. With years of experience in this field, we’re confident that we can find a solution tailored to meet your specific requirements. Reach out via email or phone and one of our knowledgeable staff will be happy to discuss all things related to export pallets with you.

Don’t hesitate any longer; take advantage of our expertise today! Our team is always available and ready to answer any questions you may have regarding international transportation solutions.

Plastic is naturally an insulator, meaning friction can cause a static charge to build up. While this is less dangerous than an ESD discharge, it is highly undesirable for many logistics processes.

1. What are the disadvantages of static charge?

A statically charged pallet acts like a magnet for dirt. This creates two primary problems in the supply chain:

- Hygiene & Quality (dust): The charge attracts dust and dirt from the environment. This can affect the quality of the packaging or the product, which is unacceptable, especially in 'clean' environments.

- Shocks & Electronics: Employees may experience unpleasant shocks upon contact, and sensitive electronics can be disrupted.

2. The solution: Antistatic additives

To prevent this, Q-Pall can optionally provide your pallets with synergistic antistatic additives.

These additives are mixed into the plastic during production and ensure that the surface resistance is lowered. As a result, static charge cannot build up, keeping the pallet clean (dust-repellent) and safe to use.

Do you experience dust accumulation or static issues in your warehouse? Contact us to discuss the possibilities for antistatic additives.

Clickable skids are detachable runners specially developed for our Q-Pall Light Series. They transform a lightweight, nestable pallet into a more stable skid pallet, without compromising on operational efficiency.

1. What is the major advantage of clickable skids?

The unique advantage lies in the savings on transport and storage costs. Because the skids are supplied separately, you benefit from the best of both worlds:

- Transport (Volume): You transport the pallets 'bare' and nested inside each other. This saves considerable loading meters in the truck compared to pallets with fixed skids.

- Usage (Functionality): On location, you simply click the skids underneath the pallet. This makes the pallet more stable, stackable, and better suited for conveyor belts.

2. Simple assembly

Technical knowledge is not required. The skids are designed in such a way that you can quickly and easily click them under the pallets from the Light Series yourself. This offers maximum flexibility in your logistics process.

Do you want to calculate how much space you can save with this system? Contact us for tailored advice.

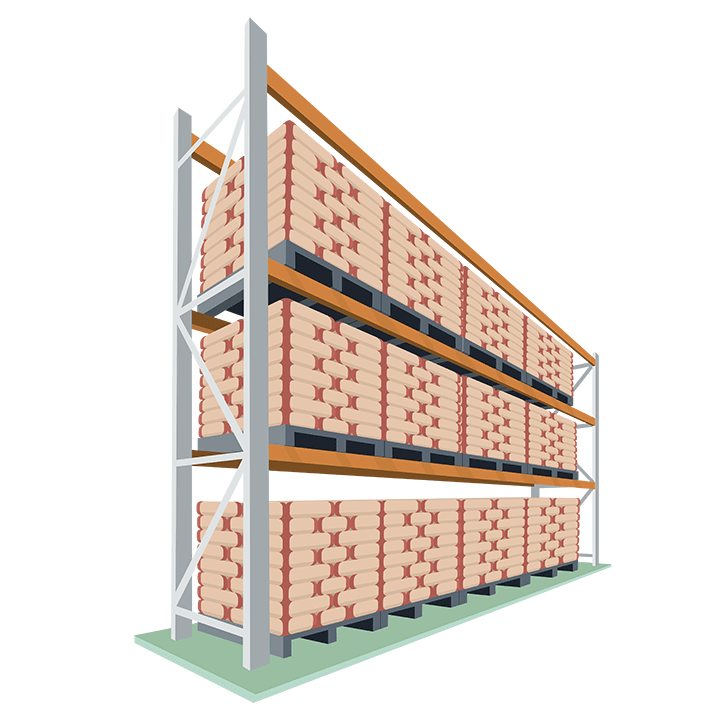

Racking Load (internationally known as Racking Load) is the maximum weight a pallet can bear when placed in a pallet racking system without decking or mesh shelves.

1. Why is this the most important value?

With this load, the pallet rests solely on the two beams of the rack (beam racking). The pallet effectively "hangs" freely in the center. This demands the utmost from the structural rigidity. Exceeding this weight leads to dangerous deflection or breakage.

2. How is this tested?

The specifications we state are based on a Uniformly Distributed Load (UDL).

During our tests, we load the pallet with 25 kg bags spread over the entire surface. This simulates a realistic practical situation.

Note: In the case of point loading (a heavy weight concentrated in one spot), the load capacity may be lower than the specified racking load; this must be tested in practice.

The carbon footprint of a plastic pallet expresses the total environmental impact in kilograms of CO2 equivalent (kg CO2 eq.). To make this impact transparent for you, official Environmental Product Declaration (EPD) documents are available for all Q-Pall pallets.

1. What does this emission consist of?

Greenhouse gas emissions occur at various stages of the life cycle. The greatest impact usually arises during:

- Raw material extraction: Obtaining the base material.

- Production: Energy consumption during the injection molding of the pallets.

- Transport: Logistics from raw material to factory and from factory to customer.

2. How Q-Pall reduces CO2

We minimize these emissions at every step of the process. By making intensive use of recycled plastics and organizing the 'end-of-life' process (full recycling of old pallets), we significantly lower the ecological footprint compared to wooden alternatives or virgin plastic.

Do you want to dive deeper into our sustainability strategy? Read all about our vision on recycling and reduction in our Orange Values.

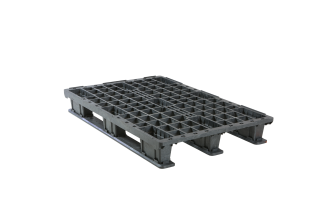

When selecting a plastic pallet, the choice of the top deck is decisive for functionality. You can choose between an open structure (gridded) for weight savings or a closed deck for hygiene and load capacity.

1. Open top deck

A pallet with an open structure contains holes or grids in the deck.

- Advantage: Less material usage makes the pallet lighter and often more cost-efficient.

- Application: Ideal for export, general logistics, and situations where every kilogram counts.

2. Closed top deck

These pallets have a completely solid surface, often with a smooth finish.

- Advantage: Higher load capacity and superior hygiene. The solid deck prevents dirt or liquids from seeping through to goods underneath.

- Application: Essential for the meat processing industry, pharmaceuticals, and environments with strict hygiene requirements (HACCP).

Are you unsure which type of deck best fits your logistics process? Contact us to review the specifications for your application.