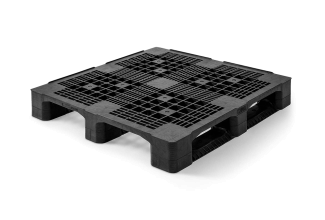

Plastic pallets

1100 x 1100

efficient container pallets for global transport

The 1100 x 1100 mm plastic pallets, like the 1140 x 1140 mm pallets, are widely used container pallets perfectly suited for transporting goods in shipping containers.

+31 (0)413 353 111

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 6,0 kg

Racking load: 0 kg

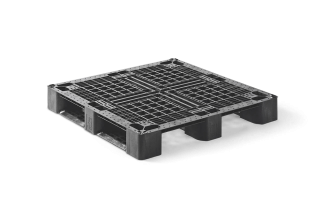

Dimensions: 1100 x 1100 mm

Height: 158 mm

Weight: 8,0 kg

Racking load: 0 kg

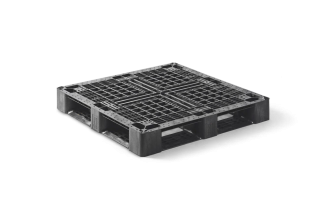

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 11,0 kg

Racking load: 250 kg

Dimensions: 1100 x 1100 mm

Height: 165 mm

Weight: 19,0 kg

Racking load: 1000 kg

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 11,7 kg

Racking load: 250 kg

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 11,7 kg

Racking load: 250 kg

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 13,0 kg

Racking load: 250 kg

Dimensions: 1100 x 1100 mm

Height: 150 mm

Weight: 13,1 kg

Racking load: 250 kg

This format is specifically designed to make optimal use of the internal dimensions of a standard shipping container, which has a width of approximately 2.36 meters. This allows the pallets to be loaded tightly and efficiently, ensuring maximum loading capacity and minimal waste of space. Q-Pall plastic pallets are made from recycled plastic, are fully recyclable, and feature a nestable design, offering additional benefits for both transport and storage.

Designed for optimal container utilization

The 1100 x 1100 mm format is perfectly aligned with the internal dimensions of standard containers. With a container width of approximately 2.36 meters, two pallets can fit side by side, maximizing space utilization. This is crucial for international sea and air transport, where every centimeter counts for cost savings and efficiency.

Advantages of 1100 x 1100 mm pallets for container transport:

- Maximum loading capacity: Tight placement in containers minimizes wasted space.

- Cost savings: More efficient loading reduces the number of containers needed.

- Stable cargo: Less movement of goods during transport due to the optimal fit.

These dimensions make these pallets ideal for exporting bulk goods, chemicals, and industrial products.

Nestable design for efficient transport and storage

The Q-Pall 1100 x 1100 mm plastic pallets feature a nestable design, meaning they can be easily stacked inside one another when not loaded. This provides significant space savings both in warehouses and during return transport.

Advantages of the nestable design:

- Up to 50% less storage space needed: Perfect for warehouses with limited storage capacity.

- More efficient return transport: More empty pallets per truck or container.

- Easy handling: Lightweight and simple to stack.

Sustainable, lightweight, and fully recyclable

Q-Pall plastic pallets are made from recycled plastic and are fully recyclable, making them an environmentally friendly choice. This aligns with the principles of the circular economy, where materials are reused to minimize waste.

The use of plastic offers several advantages over traditional wooden pallets:

- No moisture absorption: Eliminates the risk of mold or wood rot.

- Hygienic: Easy to clean and ideal for industries with strict hygiene requirements.

- Lightweight: Lower weight reduces transport costs.

- No splinters or nails: Safe for goods and employees.

- Longer lifespan: Durable for intensive reuse.

The combination of lightweight material and durability makes these pallets particularly suitable for industries with strict demands for efficiency, safety, and environmental responsibility.

Ideal for various industries

The Q-Pall 1100 x 1100 mm plastic pallets are widely applicable in various industries, including:

- International container transport: Optimized container dimensions for global shipments.

- Chemical industry: Resistant to acids, bases, and solvents.

- Food industry: Hygienic, easy to clean, and free of nails or splinters.

- Pharmaceutical sector: Hygienic and suitable for controlled environments.

- Retail and distribution centers: Efficiently stackable and space-saving.

Why choose Q-Pall 1100 x 1100 mm plastic pallets?

Q-Pall 1100 x 1100 mm plastic pallets combine efficiency, sustainability, and safety. With their nestable design and optimized dimensions for container transport, these pallets are an excellent choice for international logistics.

Key benefits:

- Perfect fit for containers (2.36 m wide).

- Nestable design saves space in storage and return transport.

- Made from recycled plastic and fully recyclable.

- Lightweight for reduced transport costs.

- Hygienic and moisture-resistant.

- No splinters, nails, or loose parts.

By choosing Q-Pall plastic pallets, your company invests in a more efficient, safer, and sustainable logistics solution.

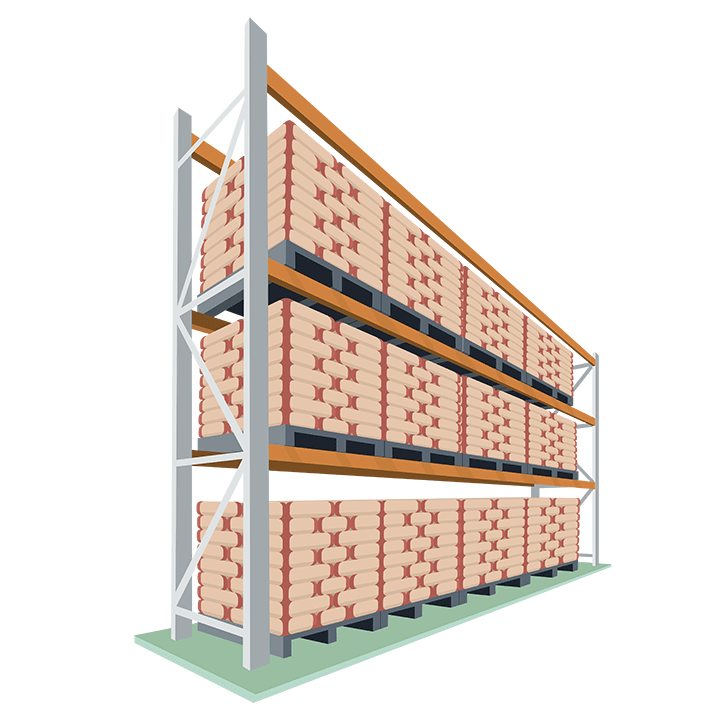

Racking Load (internationally known as Racking Load) is the maximum weight a pallet can bear when placed in a pallet racking system without decking or mesh shelves.

1. Why is this the most important value?

With this load, the pallet rests solely on the two beams of the rack (beam racking). The pallet effectively "hangs" freely in the center. This demands the utmost from the structural rigidity. Exceeding this weight leads to dangerous deflection or breakage.

2. How is this tested?

The specifications we state are based on a Uniformly Distributed Load (UDL).

During our tests, we load the pallet with 25 kg bags spread over the entire surface. This simulates a realistic practical situation.

Note: In the case of point loading (a heavy weight concentrated in one spot), the load capacity may be lower than the specified racking load; this must be tested in practice.

The carbon footprint of a plastic pallet expresses the total environmental impact in kilograms of CO2 equivalent (kg CO2 eq.). To make this impact transparent for you, official Environmental Product Declaration (EPD) documents are available for all Q-Pall pallets.

1. What does this emission consist of?

Greenhouse gas emissions occur at various stages of the life cycle. The greatest impact usually arises during:

- Raw material extraction: Obtaining the base material.

- Production: Energy consumption during the injection molding of the pallets.

- Transport: Logistics from raw material to factory and from factory to customer.

2. How Q-Pall reduces CO2

We minimize these emissions at every step of the process. By making intensive use of recycled plastics and organizing the 'end-of-life' process (full recycling of old pallets), we significantly lower the ecological footprint compared to wooden alternatives or virgin plastic.

Do you want to dive deeper into our sustainability strategy? Read all about our vision on recycling and reduction in our Orange Values.