Chemical pallets CP

A Chemical Pallet or CP Pallet is one of the many kinds of plastic pallets. This pallet was originally intended to bring unity to pallets that are used for the chemical and plastic industry in Europe. They are often referred to as CP pallets. Chemical Pallets are also used in many other industries. An important property of the CP pallet is that they retain their economic value. But what Chemical Pallets are there and what are the properties of the different pallets?

+31 (0)413 353 111

Height: 158 mm

Weight: 20,48 kg

Racking load: 1375 kg

Dimensions: 1140 x 1140 mm

Height: 150 mm

Weight: 13,31 kg

Racking load: 250 kg

Height: 165 mm

Weight: 21,93 kg

Racking load: 1000 kg

Height: 158 mm

Weight: 21,48 kg

Racking load: 1375 kg

Height: 150 mm

Weight: 14,25 kg

Racking load: 300 kg

Height: 165 mm

Weight: 24,6 kg

Racking load: 1250

When is a Chemical Pallet suitable?

CP can be used for many forms of transport and storage in various industries. They are commonly used for moving barrels with certain liquids, bags, octabins, and so-called big-bags. These big-bags are mainly used for the transport of raw materials such as powders and other fine material in granular form.

What Chemical Pallets are there?

Chemical Pallets are available in nine different models. These are denoted by the names CP1 through CP9. The difference between the pallets is in the size and how they are constructed. There is also a difference in use between the various CP pallets. Some pallets are very suitable for transporting and moving bags, others for boxes or liquids. Finally, the load plays an important role, i.e. how much weight a Chemical Pallet can be loaded with.

The dimensions of the pallets

The different CP pallets have different dimensions. The list shows the dimensions of different models. Some models have the same dimensions, but differ in construction. · CP1: 1000 x 1200 mm · CP2: 800 x 1200 mm · CP3: 1140 x 1140 mm · CP4: 1100 x 1300 mm · CP5: 780 x 1140 mm · CP6: 1000 x 1200 mm · CP7: 1100 x 1300 mm · CP8: 1140 x 1140 mm · CP9: 1140 x 1140 mm

An overview of the different models

CP-1 AND CP-6:

The CP-1 and CP- 6 pallets are mainly used for the transport of bags and boxes. The dimensions of both pallets are 1000 x 1200 mm. The main difference between the CP1 and CP6 pallet is the difference in base. The CP-1 has 3 runners. The CP-6 has a round base, which means it is used more often when stacking is necessary. This is because the base allows for a more equivalent distribution of the load.

CP-3 AND CP-9:

The CP-3 and CP-9 pallets are mainly used for barrels, octabins, and big-bags. The dimensions of both pallets are 1140 x 1140 mm. The CP-3 pallet is the version with 3 bottom boards and the CP-9 has a round base just like the CP-6

CP-4 AND CP-7

The CP-4 and CP-7 pallets are mainly used for the transport of bags. The dimensions of both pallets are 1100 x 1300 mm. Again, the difference between the two is in the base: the CP-4 is the version with 3 bottom boards, while the CP-7 pallet has six.

CP-5

The CP-5 pallet, with a standard size of 780 x 1140 mm, is often used for transport in containers.

CP-8

The CP-8 pallet is equal to the CP-9 pallet in terms of size and base. The difference is that the CP-8 pallet has a hole on top, which makes it suitable for use with big bags with bottom discharge. Do you have questions about our products or would you like more information about Chemical Pallets? For instance, do you want to know what pallets or other products are suitable for you? Please feel free to contact us for more information. We are happy to assist you!

ESD stands for Electrostatic Discharge. This is a physical process where friction causes a static charge to build up, which then suddenly discharges via a spark.

1. Why is ESD a risk with plastic pallets?

Standard plastic acts as an insulator, allowing static electricity to accumulate through minimal friction. Without the proper measures, this entails two major risks:

- Explosion hazard: In environments with flammable substances or gases, a single spark can have disastrous consequences.

- Damage to electronics: Sensitive electronic components can defect or malfunction due to the discharge.

2. The solution: ESD-safe pallets from Q-Pall

To eliminate these risks, we manufacture special ESD-safe pallets. During the production process, we add specific additives to the polymer (HDPE or PP), such as conductive carbon black.

This renders the pallet conductive rather than insulating, allowing static charge to be safely dissipated to the ground. The resistance levels are precisely tuned to your specific safety requirements.

Need advice? Contact us to discuss the specific resistance requirements for your application.

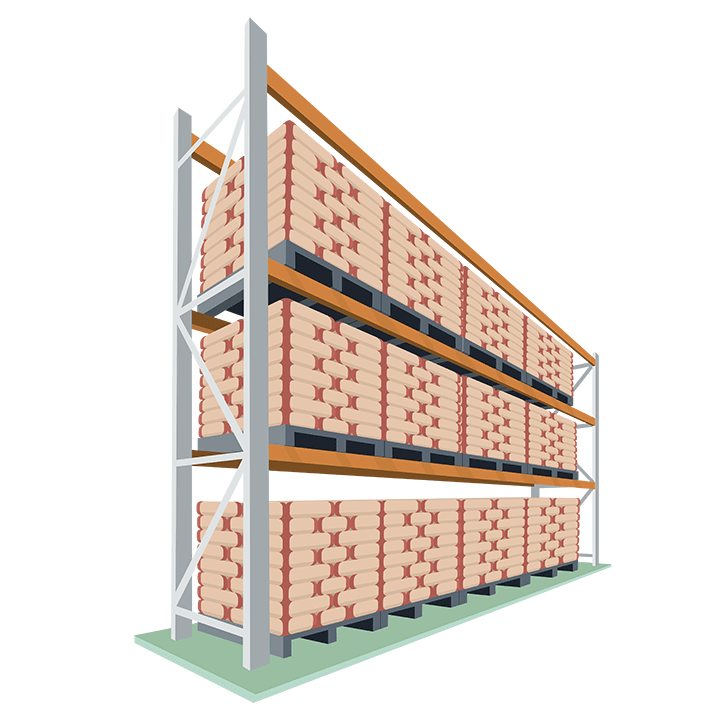

Racking Load (internationally known as Racking Load) is the maximum weight a pallet can bear when placed in a pallet racking system without decking or mesh shelves.

1. Why is this the most important value?

With this load, the pallet rests solely on the two beams of the rack (beam racking). The pallet effectively "hangs" freely in the center. This demands the utmost from the structural rigidity. Exceeding this weight leads to dangerous deflection or breakage.

2. How is this tested?

The specifications we state are based on a Uniformly Distributed Load (UDL).

During our tests, we load the pallet with 25 kg bags spread over the entire surface. This simulates a realistic practical situation.

Note: In the case of point loading (a heavy weight concentrated in one spot), the load capacity may be lower than the specified racking load; this must be tested in practice.

The carbon footprint of a plastic pallet expresses the total environmental impact in kilograms of CO2 equivalent (kg CO2 eq.). To make this impact transparent for you, official Environmental Product Declaration (EPD) documents are available for all Q-Pall pallets.

1. What does this emission consist of?

Greenhouse gas emissions occur at various stages of the life cycle. The greatest impact usually arises during:

- Raw material extraction: Obtaining the base material.

- Production: Energy consumption during the injection molding of the pallets.

- Transport: Logistics from raw material to factory and from factory to customer.

2. How Q-Pall reduces CO2

We minimize these emissions at every step of the process. By making intensive use of recycled plastics and organizing the 'end-of-life' process (full recycling of old pallets), we significantly lower the ecological footprint compared to wooden alternatives or virgin plastic.

Do you want to dive deeper into our sustainability strategy? Read all about our vision on recycling and reduction in our Orange Values.

When selecting a plastic pallet, the choice of the top deck is decisive for functionality. You can choose between an open structure (gridded) for weight savings or a closed deck for hygiene and load capacity.

1. Open top deck

A pallet with an open structure contains holes or grids in the deck.

- Advantage: Less material usage makes the pallet lighter and often more cost-efficient.

- Application: Ideal for export, general logistics, and situations where every kilogram counts.

2. Closed top deck

These pallets have a completely solid surface, often with a smooth finish.

- Advantage: Higher load capacity and superior hygiene. The solid deck prevents dirt or liquids from seeping through to goods underneath.

- Application: Essential for the meat processing industry, pharmaceuticals, and environments with strict hygiene requirements (HACCP).

Are you unsure which type of deck best fits your logistics process? Contact us to review the specifications for your application.