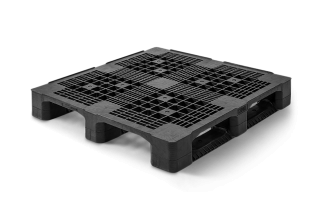

Plastic pallets

1140 x 1140

ideal for big bags and chemical applications

The 1140 x 1140 mm plastic pallets from Q-Pall are strong, durable, and safe. With fixed dimensions, consistent tare weight, and the absence of nails and splinters, they are perfect for big bags, chemical applications, and automated logistics processes. Fully made from recycled and recyclable plastic.

+31 (0)413 353 111

Dimensions: 1140 x 1140 mm

Height: 150 mm

Weight: 7,0 kg

Racking load: 0 kg

Dimensions: 1140 x 1140 mm

Height: 158 mm

Weight: 9,0 kg

Racking load: 0 kg

Dimensions: 1140 x 1140 mm

Height: 156 mm

Weight: 15,0 kg

Racking load: 200 kg

Dimensions: 1140 x 1140 mm

Height: 156 mm

Weight: 16,0 kg

Racking load: 200 kg

Dimensions: 1140 x 1140 mm

Height: 150 mm

Weight: 13,0 kg

Racking load: 300 kg

Dimensions: 1140 x 1140 mm

Height: 150 mm

Weight: 14,0 kg

Racking load: 300 kg

Dimensions: 1140 x 1140 mm

Height: 165 mm

Weight: 22,0 kg

Racking load: 1250 kg

Dimensions: 1140 x 1140 mm

Height: 165 mm

Weight: 24,0 kg

Racking load: 1250 kg

Ideal for big bags due to stability and strength

Big bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are frequently used for transporting and storing bulk materials in industries such as agriculture, chemicals, and food processing. These large bags require a stable and sturdy pallet that evenly distributes weight and prevents tipping.

The 1140 x 1140 mm plastic pallets from Q-Pall provide exactly that stability thanks to their square shape and robust construction. The evenly distributed surface ensures that even when handling heavy big bags, the load remains safe and stable during storage and transport.

Additionally, these pallets feature an open bottom design, making them easy to move with forklifts and pallet jacks. This increases efficiency in warehouses and distribution centers, especially when big bags are stacked for storage.

Suitable for the chemical sector due to resistance and safety

Q-Pall plastic pallets are ideal for use in the chemical industry, which imposes strict requirements on safety, hygiene, and material resistance. Chemical products demand pallets that can withstand corrosive substances and minimize the risk of contamination.

These pallets are completely moisture-resistant, do not absorb liquids, and are resistant to most chemicals, including acids, bases, and solvents. This prevents harmful substances from damaging the pallet material, a common issue with wooden pallets.

Moreover, the pallets are splinter-free and contain no nails or loose parts, significantly reducing the risk of damage to packaging or injury to employees. Their smooth finish also makes them easy to clean, which is crucial in environments where hygiene is essential.

For the storage of valuable or hazardous chemical loads, the robust construction of Q-Pall plastic pallets offers additional security. Their load capacity and stability ensure that goods remain safe, even under heavy loads.

Perfect for automated logistics processes

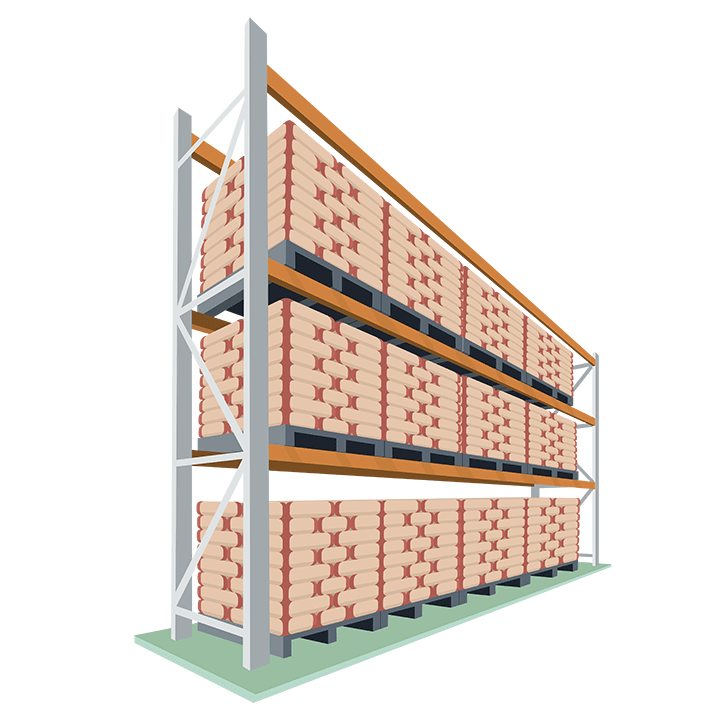

In modern warehouses and production environments, automated systems play an increasingly significant role. The 1140 x 1140 mm plastic pallets from Q-Pall are specifically designed for use in automated processes, where precision and reliability are critical.

Thanks to their fixed dimensions and consistent tare weight, these pallets can be seamlessly integrated into:

- Automated storage systems such as warehouse racks and automatic pallet storage systems.

- Conveyor belts and robots where variations in size or weight could cause disruptions.

- Palletizing machines that depend on consistent formats for efficient operation.

The absence of splinters, nails, or loose parts prevents equipment malfunctions and minimizes downtime in production. This makes these pallets ideal for high-speed production sectors where minimal interruptions are crucial.

Sustainable and fully recyclable

Q-Pall places great emphasis on sustainability and environmental friendliness. The 1140 x 1140 mm plastic pallets are made from recycled plastic and are fully recyclable, contributing to a circular economy.

The use of recycled materials does not compromise the strength or quality of the pallets. In fact, they have a longer lifespan than wooden pallets, reducing the need for frequent replacements.

At the end of their lifecycle, the pallets can be recycled again and used for producing new plastic products, reducing waste and minimizing environmental impact.

Advantages of 1140 x 1140 mm plastic pallets compared to wooden pallets

Plastic pallets offer numerous advantages over traditional wooden pallets. Here are the key benefits:

- Fixed dimensions and tare weight: Essential for automated systems and precise weighing.

- No splinters, nails, or loose parts: Enhances safety and reduces equipment malfunctions.

- Lightweight yet strong: Ideal for heavy loads without unnecessary additional weight.

- Moisture-resistant: No moisture absorption, preventing mold or swelling.

- Hygienic: Easy to clean, ideal for industries with strict hygiene requirements.

- Long lifespan: More durable than wood, with lower replacement costs.

- 100% recyclable: Made from recycled plastic and fully reusable.

Applications for 1140 x 1140 mm plastic pallets

The versatility of Q-Pall plastic pallets makes them suitable for a variety of sectors, including:

- Big bag storage and transport: Perfect for safely handling heavy bulk loads.

- Chemical industry: Resistant to chemicals and moisture.

- Automated warehouses: Ideal for use on conveyor belts and in robotic systems.

- Food industry: Hygienic, easy to clean, and safe to use.

- Pharmaceutical sector: Precise dimensions and easy to disinfect.

- Agricultural sector: Suitable for bulk goods such as grains and seeds.

The QP1140 series – the ideal choice for safe, sustainable, and efficient logistics

The Q-Pall 1140 x 1140 mm plastic pallets combine sustainability, strength, and reliability in one product. Whether it’s transporting big bags, storing chemicals, or integrating into automated logistics processes, these pallets offer a future-proof solution.

By choosing Q-Pall pallets, your company invests in an eco-friendly, cost-efficient, and safe solution for all your storage and transport needs.

Racking Load (internationally known as Racking Load) is the maximum weight a pallet can bear when placed in a pallet racking system without decking or mesh shelves.

1. Why is this the most important value?

With this load, the pallet rests solely on the two beams of the rack (beam racking). The pallet effectively "hangs" freely in the center. This demands the utmost from the structural rigidity. Exceeding this weight leads to dangerous deflection or breakage.

2. How is this tested?

The specifications we state are based on a Uniformly Distributed Load (UDL).

During our tests, we load the pallet with 25 kg bags spread over the entire surface. This simulates a realistic practical situation.

Note: In the case of point loading (a heavy weight concentrated in one spot), the load capacity may be lower than the specified racking load; this must be tested in practice.

The carbon footprint of a plastic pallet expresses the total environmental impact in kilograms of CO2 equivalent (kg CO2 eq.). To make this impact transparent for you, official Environmental Product Declaration (EPD) documents are available for all Q-Pall pallets.

1. What does this emission consist of?

Greenhouse gas emissions occur at various stages of the life cycle. The greatest impact usually arises during:

- Raw material extraction: Obtaining the base material.

- Production: Energy consumption during the injection molding of the pallets.

- Transport: Logistics from raw material to factory and from factory to customer.

2. How Q-Pall reduces CO2

We minimize these emissions at every step of the process. By making intensive use of recycled plastics and organizing the 'end-of-life' process (full recycling of old pallets), we significantly lower the ecological footprint compared to wooden alternatives or virgin plastic.

Do you want to dive deeper into our sustainability strategy? Read all about our vision on recycling and reduction in our Orange Values.