Buying CP3 Pallets?

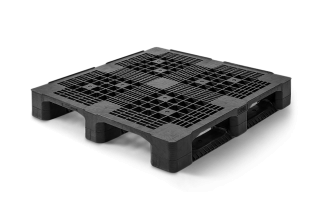

Discover Q-Pall's CP3 pallets, a leading choice in the CP pallets series designed for efficient transportation and storage of goods. Distinguished from other models in its class, the CP3 pallet offers unique features in terms of dimensions, material selection, and quality. As part of Q-Pall's plastic pallet family and the standard CP pallets range consisting of nine different models, the CP3 pallet is known for its specific characteristics that set it apart from other options in the market.

+31 (0)413 353 111

Dimensions: 1140 x 1140 mm

Height: 150 mm

Weight: 13,31 kg

Racking load: 250 kg

Height: 165 mm

Weight: 21,93 kg

Racking load: 1000 kg

What are CP3 pallets used for?

CP3 pallets are specifically designed for the transport of chemical goods, including drums, octabins, and big bags. The CP3 pallet dimensions are 1140 x 1140 mm and have a carrying capacity of approximately 1250 kg. The CP3 pallet has 3 bottom boards and an open deck. The open design allows these pallets to be easily stacked on top of each other. Please note that CP3 pallets have the same dimensions as CP9 pallets; only the CP9 pallets have a different bottom deck.

Want to order CP3 pallets?

You've come to the right place at Q-Pall for ordering CP3 pallets! On our website, you'll find a comprehensive overview of the pallets, along with product specification descriptions. Pay close attention to these product specifications to ensure you get the right pallet size. With each CP3 pallet, you have additional options to select, such as ESD, anti-slip, or fire-resistant features. Afterward, you can easily request a quote from us for the quantity of CP3 pallets you need. If you have any questions about our CP pallets, you can easily reach us through the contact form on the website or by phone or email. Our customer service is here to assist you and assess your situation!

What other types of CP pallets are available besides CP3?

CP pallets closely resemble standard pallets and, like Euro pallets, hold significant economic value. However, there are some noticeable differences. CP pallets offer a choice of 9 different models, designated from CP1 to CP9. Quality is crucial with these types of plastic pallets, and both wooden and plastic pallets are available. At Q-Pall, you'll find plastic CP3 pallets that are easy to clean and resistant to deterioration or damage. The advantage of such pallets is their ease of reuse.

More information about CP3 pallets

For more information about CP3 pallets, to request a quote without obligation, or to buy CP3 pallets, Q-Pall, with the largest selection in the market, is here to assist you. Contact us by sending an email to info@qpall.com or by calling our specialists at 0413-353 111."

1. Material Choice & Application

The exact composition depends on the intended use:

- Standard & Pool Pallets: Made from recycled material for maximum sustainability and durability.

- Food Safety (HACCP): For direct contact with food, we use no recycled material, but exclusively virgin PP or HDPE.

2. Recycling & Circularity

Because our pallets consist of 100% plastic, they are fully recyclable at the end of their service life. This supports a circular process: your old pallet becomes the raw material for a new Q-Pall pallet.

Skids, often referred to in logistics as runners, determine the stability and usability of a pallet. They ensure the connection with the floor, racking, or conveyor system.

Which configuration do you need?

The choice depends on your storage system and the vulnerability of your load. These are the three most common variants:

- 3 Skids (Longitudinal)

Ideal for: High Racking & Automation.

This is the standard for racking systems. Pallets with three longitudinal skids rest stably on the beams and are perfectly suited for automated conveyor systems. - 5 Skids (Perimeter Base)

Ideal for: Flexible Logistics & Pallet Jacks.

This configuration often forms a 'frame' around the perimeter but leaves the center open. This makes it easier for forklifts and pallet jacks to pick up the pallet from all sides, speeding up the process in block stacking scenarios. - 6 Skids (Cross Deck)

Ideal for: Block Stacking & Pressure Distribution.

This is the heaviest and most stable variant with a full cruciform base.- Maximum pressure distribution: The large surface area at the bottom prevents the pallet from pressing into the underlying load. This prevents damage to boxes or bagged goods.

- Robustness: Due to maximum rigidity, this variant is superior for intensive block stacking.

Are you unsure which base structure fits your warehouse system? Contact us; we are happy to advise you on the right configuration.

The load capacity indicates the maximum weight a plastic pallet can safely bear. This is the most important specification for your choice, as overloading can lead to damage or unsafe situations.

1. What determines the load capacity?

The construction and the material used determine the strength of the pallet. A smartly designed plastic pallet combines a low tare weight with a high load capacity. However, a pallet with a higher load capacity is not by definition 'better'; it is about ensuring the specifications match your intended use.

2. The three types of load

Load capacity is never just one fixed number. In technical specifications, we distinguish between three situations:

- Static load: The maximum load when the pallet is stationary on the ground (e.g., during storage or stacking).

- Dynamic load: The maximum load during transport with a forklift or pallet jack.

- Racking load: The maximum load when the pallet is placed in a rack, supported by beams.

Note: The values for these three situations differ significantly per pallet.

Are you unsure which load capacity is required for your logistics process? Contact us; we are happy to help you find the right match between load and pallet type.

The carbon footprint of a plastic pallet expresses the total environmental impact in kilograms of CO2 equivalent (kg CO2 eq.). To make this impact transparent for you, official Environmental Product Declaration (EPD) documents are available for all Q-Pall pallets.

1. What does this emission consist of?

Greenhouse gas emissions occur at various stages of the life cycle. The greatest impact usually arises during:

- Raw material extraction: Obtaining the base material.

- Production: Energy consumption during the injection molding of the pallets.

- Transport: Logistics from raw material to factory and from factory to customer.

2. How Q-Pall reduces CO2

We minimize these emissions at every step of the process. By making intensive use of recycled plastics and organizing the 'end-of-life' process (full recycling of old pallets), we significantly lower the ecological footprint compared to wooden alternatives or virgin plastic.

Do you want to dive deeper into our sustainability strategy? Read all about our vision on recycling and reduction in our Orange Values.

When selecting a plastic pallet, the choice of the top deck is decisive for functionality. You can choose between an open structure (gridded) for weight savings or a closed deck for hygiene and load capacity.

1. Open top deck

A pallet with an open structure contains holes or grids in the deck.

- Advantage: Less material usage makes the pallet lighter and often more cost-efficient.

- Application: Ideal for export, general logistics, and situations where every kilogram counts.

2. Closed top deck

These pallets have a completely solid surface, often with a smooth finish.

- Advantage: Higher load capacity and superior hygiene. The solid deck prevents dirt or liquids from seeping through to goods underneath.

- Application: Essential for the meat processing industry, pharmaceuticals, and environments with strict hygiene requirements (HACCP).

Are you unsure which type of deck best fits your logistics process? Contact us to review the specifications for your application.