local production

Transporting pallets from one central point to customers across Europe? At Q-Pall, we believe that’s outdated. Since our founding, reducing transport movements has been central to our approach. Why? Because less transport not only lowers costs but also directly contributes to a more sustainable future.

Sustainable and affordable

Transporting pallets from one central point to the rest of Europe is an expensive matter. In addition to the 500 pallets that can fit in a truck on average, such a truck mainly transports air. Over long distances. This way of working quickly makes each pallet several euros more expensive.

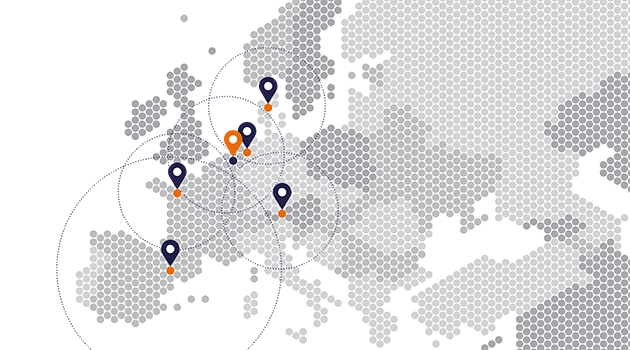

That’s why Q-Pall produces close to its customers. We have factories in Denmark, Germany, France, and Spain. This means that we are never more than 600 kilometers away from our customers. In this way, transportation becomes less costly, and we reduce CO₂ emissions.

Sustainable supply of recycled material

Conversely, the cost reduction and environmental gains also apply to the supply of materials. The material for our pallets comes from all over Europe. Instead of collecting and transporting it to one central factory, we ensure that the material is delivered to the production facility closest to the source. This means that we not only save on transport costs but also significantly reduce CO₂ emissions by limiting the number of transport kilometers. A win-win: lower costs for the company and a positive impact on the environment. By optimizing our logistics processes in this way, we contribute to a more efficient and sustainable supply chain.

Runners in stock

We ensure that the best-selling pallets, the so-called fast movers, are in stock at every factory. This way, we can deliver quickly and efficiently. But we also have a great solution for customer-specific and project-related pallets. Instead of keeping production centralized at one location, we move the mold to the factory closest to the end customer. The customer ultimately sees this reflected in the price, and there are significant CO₂ savings as well.

Security above all - second source

Having multiple production locations in Europe offers another great advantage for the customer. We always have a second factory available where we can produce customer-specific pallets. If there is a production problem at the facility where a particular type of pallet is made, or worse, if a factory burns down, one of the other locations takes over the production process with the copy mold. This way, customers are always assured that their production can continue without interruptions.