Read time: 5 minutes

Executive summary

In a geopolitically unstable world, nearshoring has transformed from a strategic option into a hard requirement for risk management. Organizations focusing on continuity and ESG compliance realize that local production of logistics assets offers three crucial advantages: operational resilience, a direct reduction of Scope 3 emissions, and financial stability through lower TCO.

Table of Contents

The vulnerability of the 'global factory'

For decades, logistics logic dictated that production should take place where wages were lowest. 'Offshoring' was the standard for cost reduction. However, recent macroeconomic events have painfully exposed the hidden costs of this model. Supply chain directors are faced with a 'perfect storm' today that demands a fundamental revision of procurement strategy.

Geopolitical friction and uncertainty

Today's reality is erratic. Conflicts in Ukraine and persistent tensions around crucial trade routes like the Red Sea cause not only human suffering but also unpredictable delays in the chain. A route that was safe yesterday is uninsurable today. For companies dependent on imports, this means lead times become fluid and margins evaporate due to exploding transport and insurance costs.

The impact of new ESG legislation

Additionally, regulatory pressure plays an increasingly large role. The introduction of the CSRD (Corporate Sustainability Reporting Directive) forces companies into full transparency. It is no longer sufficient to know that you will receive delivery; you must account for where it comes from and what the ecological impact is. Importing commodity products like pallets from outside Europe becomes a risky venture in this light. After all, how do you justify a high CO₂ footprint for a logistics carrier in your annual report?

Strategic lever: the Q-Pall model

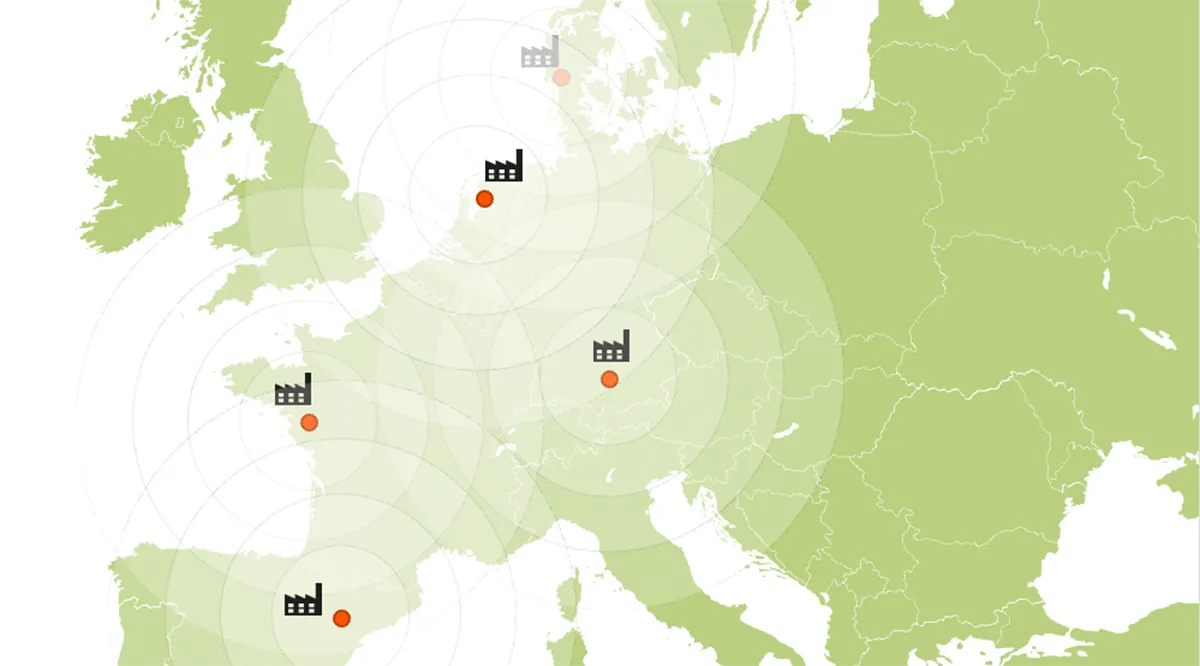

At Q-Pall, we approach production not as a simple cost item, but as a strategic instrument for security of supply. We have consciously chosen a model of 'nearshoring'. By producing at five strategic locations within Europe, we eliminate the 'single point of failure' that characterizes many global chains.

This model offers a fundamentally different dynamic than traditional imports. Whereas intercontinental sea freight is susceptible to weeks of delays, our network allows us to switch and deliver within days. We are not dependent on one port or one route; we utilize a fine-meshed, regional distribution network.

"In practice, local production means you no longer have to buffer for uncertainty. You reduce your working capital because lead times are short and guaranteed."

Moreover, this regional approach ensures price stability. While container rates fluctuate based on global scarcity, local transport costs remain relatively stable and predictable. For the CFO, this means less volatility in procurement costs; for the Supply Chain Manager, it means peace of mind in operations.

Figure 1: Strategic spread of production locations guarantees short lines to all European markets.

Circularity as a hard KPI

Another, often underexposed aspect of local production is the control over the raw material flow, or the 'Chain of custody'. This is essential for companies that take their ESG objectives seriously and want to avoid greenwashing.

Control over the source

Our plastic pallets are manufactured from recycled High-Density Polyethylene (HDPE), recognizable by RIC code 2. Because we source locally, we have direct insight into the quality and origin of the recyclate. We prevent waste streams from being dragged halfway across the world before they get a new life. This is circularity in its purest form: local waste becomes a local raw material, which is converted into a local product.

The result is a product that is technically superior – unbreakable, weather-resistant, and hygienic – but also a product that tells an honest story in your sustainability report. At the end of its life, the pallet is 100% recyclable within that same regional chain.

Conclusion: the future is regional

In a world that is changing ever faster, companies must anticipate, not react. Local production is not a buzzword in this context, but a structural choice for resilience, sustainability, and competitiveness. It shifts the focus from 'lowest price per unit' to 'lowest risk and highest value for the chain'.

Is your supply chain 'future-proof'?

Do you want insight into what the switch to locally produced plastic pallets means for your TCO and ESG performance? We are happy to calculate it for you.

Request a supply chain benchmark