In short

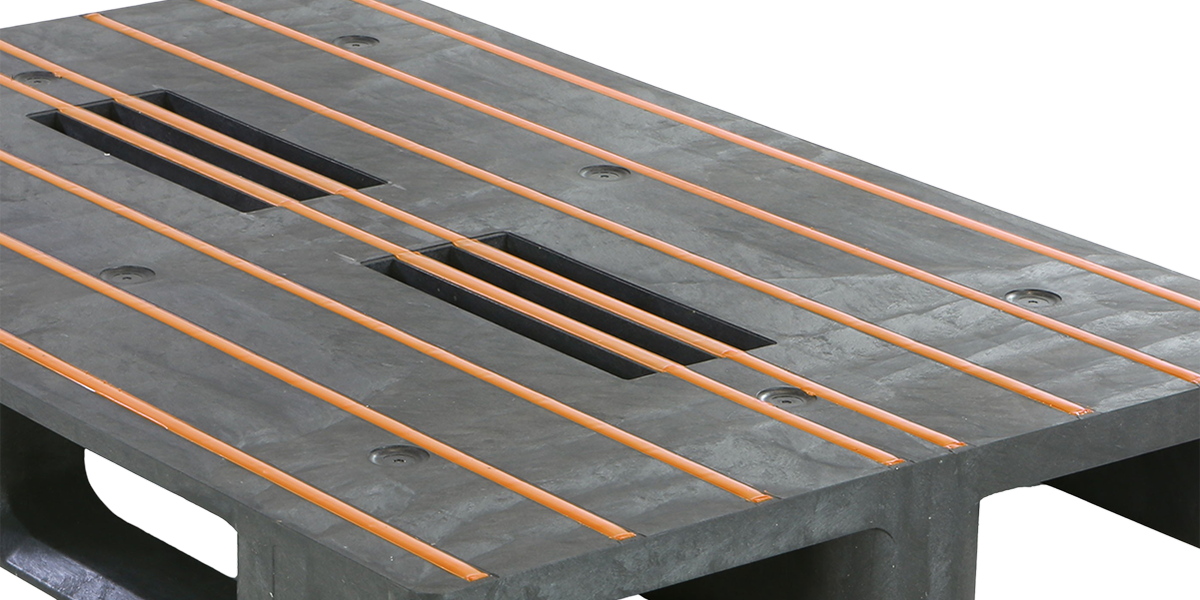

- The innovation: New medium pallets (1200x800 & 1200x1000) with an integrated anti-slip top deck.

- The problem: Shifting loads cause product damage, safety risks, and disruptions in automated lines.

- The solution: Maximum grip with an optional safety rim for various load carriers.

- Sustainability: The anti-slip strip is fully recyclable; material separation is not required.

The solution seems simple, but is crucial for any logistics operation: grip. As the creator of the medium plastic pallet, Q-Pall continues to innovate on the standard we set ourselves. That is why we are now introducing the next generation of medium pallets, equipped with a superior, integrated anti-slip top deck.

Why load securing is the foundation of logistics

Load securing is one of the most underestimated aspects of logistics transport. A pallet in motion, whether on a forklift, a conveyor belt, or in a truck, must remain stable. When boxes or crates start to slide, immediate problems arise in the chain:

- Safety risks: Falling loads can seriously injure employees.

- Product damage: Damaged goods become unsellable, directly impacting your margin.

- Process disruption: In automated warehouses (such as with AGVs), a single shifted box can cause a sensor to trigger an error and halt the entire production line.

The new standard: grip and flexibility

To meet the growing demand for safety and automation, we have further developed our medium range. These pallets are available in standard dimensions 1200x800 mm and 1200x1000 mm.

In addition to the improved anti-slip layer, we now offer maximum flexibility for your specific load carriers. The pallets are available in two variants:

- Without rim: For loads that may slightly overhang the pallet.

- With safety rim: For an extra physical barrier against boxes or crates sliding off.

4 benefits for your supply chain

Switching to these renewed medium pallets provides four concrete benefits:

- Increased safety:

The load remains firmly in place due to the friction of the anti-slip strips. The risk of sliding decreases drastically, even during internal transport. - Less packaging material:

Pallets are often excessively wrapped with stretch wrap for stability. Because the pallet itself offers more grip, less foil is needed. This saves costs and reduces plastic waste. - Higher throughput:

In distribution centers where speed is essential, stable loads ensure a smoother process. Conveyor belts can run at higher speeds without malfunctions. - Ready for automation:

Logistics is automating at a rapid pace. Automated Guided Vehicles (AGVs) and roller conveyors require standardization. These new pallets are specifically designed for seamless integration in high-tech environments.

Sustainability without compromise: 100% recyclable

At Q-Pall, we believe that innovation must go hand in hand with circularity. A common problem with traditional anti-slip solutions is that rubber strips are often difficult to recycle or must first be removed manually.

With our new medium pallets, this is a thing of the past. The anti-slip rim used is fully compatible with the recycling process of the pallet itself. This means the strip does not need to be detached at the end of its life cycle. The pallet can be ground in its entirety, all at once, into granulate for new Q-Pall pallets.

Optimize your logistics flow

A pallet is the foundation of your logistics process. Choose safety, efficiency, and sustainability with the renewed medium pallet.

Are you curious whether the variant with or without a safety rim fits your flow best?

Direct contact