The global economy is undergoing a transition. The decades-long focus on globalization—where production was outsourced to the lowest bidder, regardless of location—has reached its limits. From disruptions in container logistics to international trade tensions and raw material shortages, companies have experienced more than ever how fragile globalized chains can be.

For supply chain directors, COOs, and sustainability leaders, this is the moment to steer towards resilience. And resilience starts locally.

Local production is not a temporary solution to a global problem. It is a structural reorientation that makes companies future-proof—strategically, operationally, and sustainably.

Local production: three strategic advantages

1. Less dependence on global disruptions

In a time when reliability is more important than ever, local production offers tangible benefits:

-

Short, predictable delivery times: No queues at ports or border controls, but direct delivery from regional hubs.

-

Less vulnerability to geopolitical risks: Wars, sanctions, or export restrictions have less impact when you produce closer to home.

-

Better control over inventory and flexibility: Local production enables you to scale up or down quickly in response to sudden changes in demand.

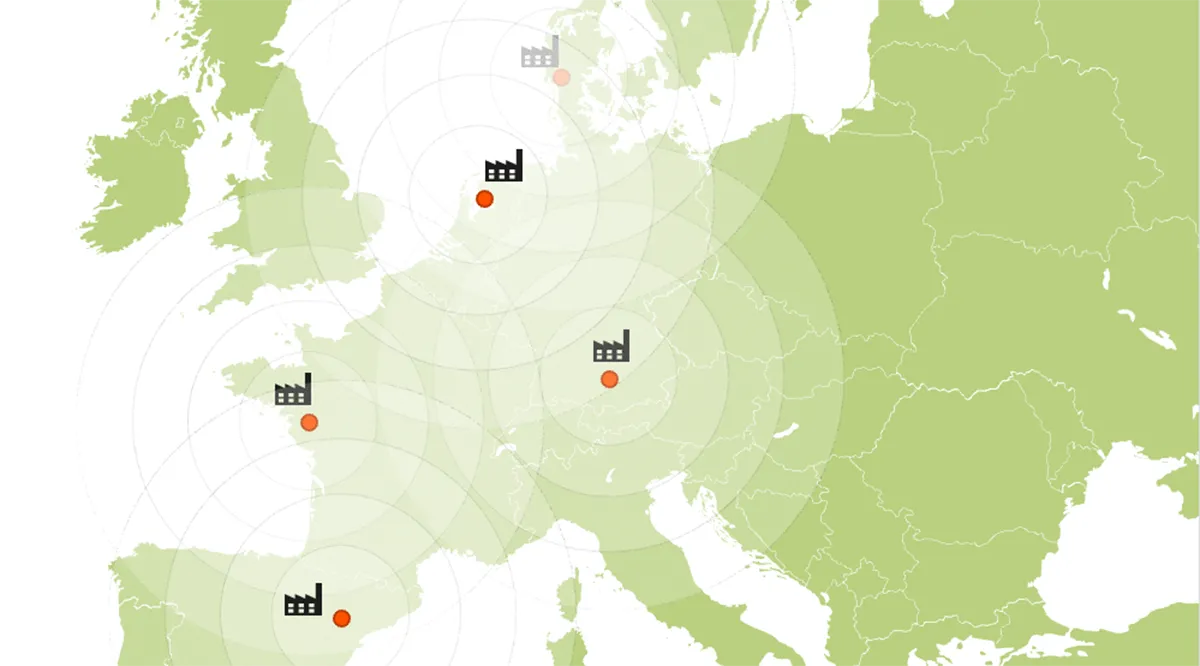

In practice: Q-Pall produces plastic pallets in five European countries. As a result, we can deliver within days instead of weeks—crucial in sectors where delivery reliability directly affects continuity.

2. CO₂ reduction and strong ESG performance through local sourcing

What often remains underexposed but is crucial: not only the location of production but also the origin of raw materials determines the real sustainability impact.

-

Local sourcing of recycled plastics means shorter supply lines, less emissions, and a contribution to the circular economy.

-

It increases transparency and traceability in your material usage—essential for credible ESG reporting.

-

By utilizing local residual streams, you support regional recycling industries and enhance your societal relevance.

Q-Pall case: We use only RIC code 2 plastic—fully recyclable and locally sourced. In the past year alone, we processed several tens of thousands of tons of recycled materials from Europe. That's equivalent to about 1,400 full truckloads that didn't have to come from distant continents.

3. Cost efficiency through stability and speed

Although local production may sometimes seem more expensive on paper, it provides structural advantages:

-

Lower transport costs: Short distances and direct deliveries significantly reduce logistics costs.

-

Higher delivery reliability prevents inventory surpluses, rush deliveries, or shortages due to stockouts.

-

Quality assurance and fewer failure costs: Closer collaboration with local production partners improves process control and reduces return flows.

What customers notice: Q-Pall customers report a decrease in failure costs, less inventory buffer, and above all: peace of mind in their supply chain. This directly translates to a lower Total Cost of Ownership.

Strategic steering in a new reality

The future of supply chains is no longer purely global or purely local. It's about smart distribution, strategic partnerships, and direct impact on sustainability and efficiency. Local production and local sourcing are not side issues but crucial building blocks of a robust chain strategy.

At Q-Pall, we believe that every logistics tool—even the often-overlooked pallet—can be a strategic lever for innovation, risk management, and sustainable growth. By producing locally with locally recycled materials and prioritizing delivery reliability, we help companies build a circular, resilient supply chain.

Curious how local production and sourcing can make your chain stronger, more sustainable, and more profitable? Contact us for CO₂ savings in your logistics. Together, we’ll get your supply chain in top condition.